Aluminum Extrustion Framing, Supports and Hardware

The aluminum extrusion process transforms aluminum blend into cantankerous-sectional products. This process has an incredibly wide variety of dissimilar applications. Aluminum is peculiarly well-suited for extrusion, every bit information technology is uniquely malleable and stable.

Aluminum Extrusion Design

When starting time the process of aluminum extrusion design, there are many factors to be considered. 1 of the showtime and most important variables is circle size — it is vital to find a manufacturer that handles the desired circle size, as not every manufacturer offers a full range of options. Additionally, weight-per-foot must exist taken into account earlier beginning the blueprint process. These measurements can bear on the operation of the press and make up one's mind the necessary press size.

To achieve the best production, designers must besides account for shape constraints. For the extrusion process to work optimally, it is best to avoid high tongue ratios.

Best Practices

There are a number of design practices that can help to ensure a ameliorate final production. These include:

- Utilization of webs, grooves, and ribs

- Generous tapers

- Counterbalanced walls

- Avoiding or limiting hollows

- Minimizing the perimeter/cross-section ratio

- Practicing symmetry and limiting asymmetrical details

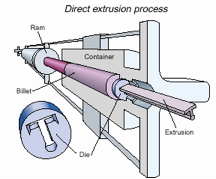

There are two extrusion processes, direct and indirect. With direct, the ingot moves relative to the container wall; with indirect, the die moves. Under pressure, the ingot or barracks, bars in a container, is forced through a die opening to grade an elongated shape or tube. To produce a tube or hollow shapes, a mandrel establishes the inside profile. Mandrels tin can either be dissever tools or an integral part of specialized dies.

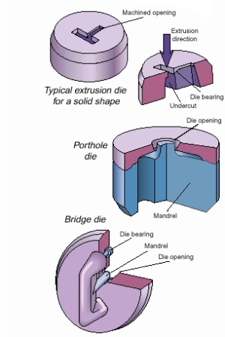

There are iii types of extrusion dies — porthole and bridge designs for hollow shapes and machined blanks for solid shapes. Dies are usually machined from A13 steel at 47 to 51 Rockwell B.

It has been proven many times over that designers who are well-versed in technology produce the most successful designs. In the case of designing extruded aluminum parts, practitioners need a good background in alloy properties, relative material and tooling costs, and the latest manufacturing techniques.

It has been proven many times over that designers who are well-versed in technology produce the most successful designs. In the case of designing extruded aluminum parts, practitioners need a good background in alloy properties, relative material and tooling costs, and the latest manufacturing techniques.

Certain aluminum alloys lend themselves well to the extrusion procedure. Extrusion is an economical mode for designers to create parts with individually engineered shapes. This versatility lets designers place metallic merely where it is structurally needed or hollow out parts for greater utility and economy.

With aluminum extrusions, there is no need to limit design shapes to "standard" profiles equally is often a requirement with steel and other materials. The power to tailor shapes for each application besides helps consolidate parts and eliminate secondary joining processes common with designs made from sheet stock.

It is paramount for virtually designers to have a clear knowledge of 6000 (Al-Mg-Si) Series alloys, by and large 6061 and 6063. Alloy 6061 is often referred to every bit the "plain carbon steel of aluminum" — the workhorse standard for structural parts. And though other alloys fit the bill for special needs, 6061 is 1 of the almost cost effective. It is considerably stronger than common aluminum-canvass alloys such equally 5052 H32. It has a 35,000 psi yield force compared to 23,000 psi for 5052 H32.

Ane of the biggest mistakes designers make in blend specification, however, stems from concerns over forcefulness. High-force alloys referenced in the Aluminum Standards may at first glance announced to be appropriate for a new blueprint. But at that place may be hidden drawbacks associated with these specialized alloys which preclude mutual use, high cost beingness only one.

For case, 7075-T6 aluminum has a minimum yield strength of seventy,000 psi. But, the alloy can't produce intricate shapes, isn't weldable, and is prone to corrosion. For an aircraft fly spar, it may well exist an excellent choice, only for a truck frame information technology will likely cost likewise much and not perform well.

It is also of import to note that college material strength doesn't necessarily boost role rigidity. A stronger aluminum alloy will help merely if peak or circadian loading conditions make it imperative to use a higher strength material.

If the long cycle fatigue or curt cycle top loads in a part practice not exceed the adequacy of the lower strength alloy, then a higher force blend does not add to rigidity. In general, a 50% increase in thickness will make an aluminum part as potent every bit steel but at half its weight.

Extruded Aluminum Alloy Selection

The nearly common aluminum alloys for extrusion are:

1100 — It's soft and has essentially no added ingredients. Although not estrus treatable, it can be extruded into complex shapes that take a skillful brilliant finish. This alloy finds utilize in appearance items and heat-exchanger tubes.

3003 —The 3000 Series alloys are usually simply extruded for heat-exchanger tube.

6063 — A skillful match for decorative purposes with a good surface finish or for features difficult to extrude such equally thin walls or fine details. It extrudes fairly easily and is available in multiple tempers. The alloy also has 25,000 psi minimum yield and thirty,000 psi minimum ultimate strength when T6 tempered. It resists corrosion but has a depression weld strength though it welds readily.

6061 — Stronger than 6063, this alloy is a structural staple in the transportation and machined parts industries. Information technology has a proven track tape and an extensive database of backdrop which include minimum ultimate yield and tensile strengths of 35,000 and 38,000 psi, respectively. The blend extrudes and welds readily. These attributes coupled with loftier fracture toughness and proficient fatigue strength have made it a shoe-in for welded structural members which include auto, truck and trailer frames, railroad cars, and pipelines.

7004 — One in a family of "depression cease" 7000 Series (Al-Zn) alloys that are press estrus treatable, reasonably extrudable, and toll a little more 6061. High-weld strength, over 30,000 psi compared to twenty,000 psi for 6061, is a major plus. The 7000 Series has historically been widely applied in the sporting goods, bicycle, and motorcycle industries. The 7004 alloy has ultimate yield and tensile strengths above 40,000 and fifty,000 psi, respectively.

Factoring in Cost in Aluminum Extrusion Design

In comparing aluminum product forms & alloys, an extrusion is said to cost about the same as coiled canvas — at 48 in. or then wide. Getting the canvass slit to a narrow width, cut off, and formed sequentially adds cost to the function. At the terminate of the sequence, the part has the properties found in an extrusion. The divergence is that the extrusion has all those properties in the based priced lineal without the add together-ons. The extruded parts are also typically stronger and lighter than their formed-sheet counterparts.

Compared to castings, the greatest cost saver is in tooling. It is not un-usual for semipermanent mold tooling that produces pocket-size parts to toll upward of $30,000. Larger part tooling can tip the scale at over $100,000. For extrusions, many pocket-sized custom dies go for under $1,000 and seldom surpass $five,000 even for large and complex hollows.

The casting industry besides typically charges customers for replacement tools when the originals wear out. Extrusion suppliers, by convention, ordinarily pay for replacement dies.

Furthermore, it is not uncommon to spend $one,000 or more to car paradigm parts from solid stock. With extrusions, designers spend virtually about the same amount on beginning article dies which also serve production when proven. Another factor is the fourth dimension, oftentimes months, that it takes to make and prove casting tools. Extrusion dies, on the other hand, frequently accept only a few weeks to build and prove.

Design Trouble Spots for Aluminum Extrusions

The more than unsymmetrical or unbalanced a shape, the less likely it is to remain straight or agree curves and general dimensions. Major wall-thickness variations also crusade issues. Generally, the minimum wall thickness should be at least half that of the thickest inside a profile. Distortion can be a problem otherwise. Walls with dissimilar thicknesses also cool at different rates during estrus-care for quenching, and add distortion as well.

Inexperienced designers frequently specify walls that are likewise thin. The minimum wall thickness goes up every bit the extrusion shape gets larger. In well-nigh alloys, for example, a 0.062-in. wall is possible in a three-in.-broad shape but non possible for 1 10-in. wide.

Narrow shapes with deep gaps can cause problems. An example is an opening that is 0.25-in. broad but more than than an inch deep. Hither the die steel forming the opening is hard to support and decumbent to interruption. Ratios of depth-to-opening should be kept under 4:1.

Similarly, some shapes that are non actually hollow must be produced on a hollow-type dice. Otherwise the area of the die tongue tin can't withstand the extrusion pressure forcefulness and will break.

Aluminum Extrusion Terminology

The extrusion industry has its own set of special terms pertaining to press and dice work.

Circle size: The smallest circumvolve that completely encloses a part'southward profile. This is an important indicator of producibility. It helps determine the size of the press needed to produce the shape. Some shapes will exist as minor equally ane-in. circumvolve size. Up to 12-in. circle sizes are common. Circle sizes from nineteen to xxx in. exist, but are highly specialized and the shapes tend to be quite expensive.

Press tonnage: Extrusion presses are referred to by tonnage — the amount of force available on the ram to printing the billet through the die. Nether 1,000 tons is considered quite small, while ane,100 to 5,000 tons is common. Presses up to 12,000 tons are highly specialized.

Factor: An indicator of how difficult the profile volition be to extrude. Gene is the ratio of the circle size to the surface perimeter. For example, a round solid rod would have a low factor of peradventure eight. A round shape with many splines around the periphery might have a cistron of fifty.

Extrusion ratio: Similar to Factor in that it is an indicator of difficulty. Information technology is the ratio of the cross-sectional areas of the shape of the die opening to that of the container through which the billet is pushed. A large-bore billet pushed through a very small die opening has a high reduction ratio. It may not be possible to extrude such a part. Ratios of 75:1 are common, though difficult.

The solution, however, for a difficult ratio shape is to make the part on a press with a smaller container. Another option is to use a multihole dice that lets a number of profiles extrude simultaneously. Multihole dies also come in handy for small shapes that are too long to handle practically with fifty-fifty the shortest billets the press can extrude.

There are iii types of hollow shapes, porthole dice, bridge die, and seamless tube.

Porthole die hollows: The nearly common and cost-effective way to produce a shape with a pigsty inside. The shapes are ranked in the club of difficulty as Class I, Two, or Iii. The ii-function die assembly divides the ingot being extruded, then "welds" the metal dorsum together every bit it passes through the internal die passages and the orifice fabricated past the die opening and mandrel. Material produced in this style is a hybrid product with metallurgical seams that are not visible. Porthole hollow parts are not commonly used for high-pressure level applications.

Bridge die hollows: Same as porthole except the die design is different. A Bridge die suspends the mandrel, which forms the inside void shape, behind the main die housing. At the end of each barracks extruded, the dice is stripped clean. In a porthole die, the mandrel is internal, and succeeding billets are "attached", finer making a continuous extrusion for guiding from the press.

Seamless tube: This production is produced past piercing the billet prior to extruding and the piercer, or mandrel, becomes the inside bore of the tube. There are no "welds" of whatever kind. Because the material is seamless, the formed parts can withstand high pressures. The process is generally used for round or square profiles. Inside shaped geometries take limitations.

0 Response to "Aluminum Extrustion Framing, Supports and Hardware"

Post a Comment